Ever wonder how those LCD screens get so thin? The LCD part is actually pretty thin itself, usually about a millimeter thick. That’s a marvel of manufacturing by itself, but an LCD screen actually produces no light. In fact, it blocks light.

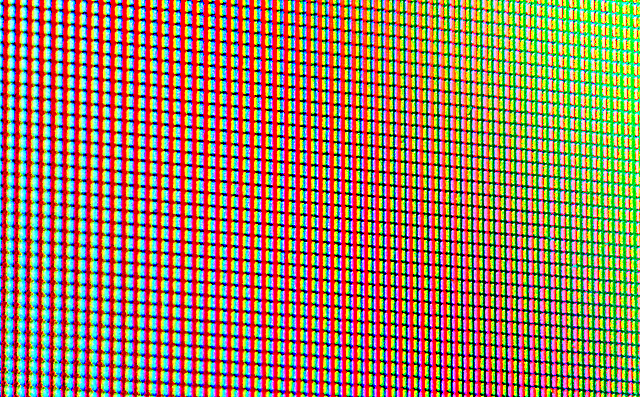

The LCD part itself is a series of elements that block some colors and not others. It’s a lot of heavy duty physics, but think of it like a series of colored lenses. If your glasses had red lenses, a light shone at you would look red. There are three LCD elements for each screen pixel: a red one, a green one, and a blue one. Most people have seen this. The lenses can automatically turn on and off, so they can be completely transparent (letting white light through) or completely opaque (letting almost no light through.) But no matter what it does, the LCD panel itself doesn’t create any light.

Every LCD panel relies on some sort of backlight to get the job done. In most cases the backlight is really just a specialized form of light bulb. It can be a compact fluorescent or an LED. In either case it’s just putting a big patch of white light behind the LCD so you can see the images formed there.

Of course, if the light behind the screen (referred to as a backlight) looked like any old compact fluorescent, it wouldn’t light evenly and it would be really thick. Fluorescent backlights can very thin, just fractions of an inch. They use a frosted sheet of plastic called a “diffusion sheet” to spread the light as evenly as possible.

In today’s televisions though, even a fraction of an inch isn’t good enough. The latest TVs are half an inch thick, including everything. There’s barely enough room for the LCD panel, the electronics, and the plastic outer shell. So what’s the trick? A sidelight.

Technically there is no such thing as a sidelight, unless you’re talking about those windows to the left and right of doors. However, the term has been used for a backlight where the primary light source is on the side. A row of LEDs sits on one side of the screen and shines out to a slightly angled metal pan that reflects it toward the screen. The whole thing is precisely engineered so that the light is as even as possible, although it’s never perfectly even. The image at the top of this article shows what a sidelight looks like. Again, a diffusion sheet is used to keep things as even as possible.

Very high end TVs use an entire sheet of LEDs behind the LCD panel so the picture lighting is controlled more precisely. This technique is referred to as “local dimming” because instead of the LCD merely blocking the light behind it, the light source exactly behind the LCD pixel is actually dimmed or turned off completely. Even more expensive prototype TVs use something called OLED technology which does away with the LCD panel altogether in favor of rows and columns of LEDs. This technology is far too expensive for large screens and today is mostly used on smartphones where space saving is at an absolute premium.