This is 2012. Forget for a minute that we’re all supposed to have flying cars by now. Aside from that, the future’s pretty bright. We’ve all got huge, flat TVs, 50 channels over the air… so what are you doing with those rabbit ears?!? It’s time to upgrade.

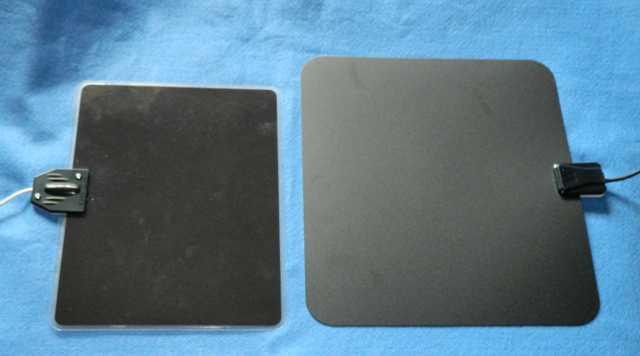

I’ve got two of the coolest antennas ever to test… the Winegard FlatWave and the Mohu Leaf. The Mohu Leaf’s been getting a lot of press and the Winegard FlatWave is mostly unknown. I took them both apart to see what makes them tick.

Both of these antennas work because of two principles. First of all, antennas don’t need to be thick. In the past, antennas were thick because they needed to stand up. Both of these antennas use wide, flat elements encased in plastic so they stay put. The elements are wide so they pick up a lot of signal, but they don’t need to be thick at all.

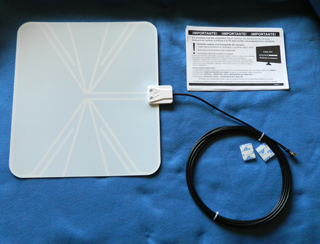

You can see the elements in the Winegard FlatWave’s white side.

The only part of either antenna that’s thicker than a sheet of paper is the base, which is still only a couple of centimeters thick. I took both apart to see what was up.

This is the base of the Winegard FlatWave. I immediately noticed a rubber boot at the cable junction where the Leaf didn’t have one. First point: Winegard FlatWave.

Both antennas have a small transformer that changes the 300 ohm resistance of the antenna to 75 ohm. There is probably some more stuff in there too. There really has to be. If they had left the antenna cable at 300 ohm they could have used flat wire and that would have made more sense. There’s probably more electronics in there.

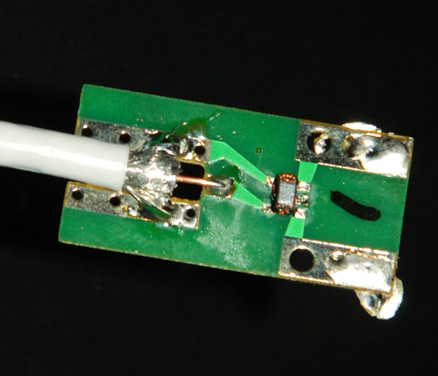

This is the circuit board inside the Mohu Leaf. It’s sitting on a very thin layer of foil that tore as soon as I got the cover off. Yeah, I know I shouldn’t have taken the cover off. But sue me, I’m curious. But now, so you know… DON’T DO THIS. You’ll break the antenna for sure.

From the looks of this, the circuit board was soldered in by hand. The solder joints are really sloppy. Overall, the circuit board looks like it was poorly put together and I wonder how long this antenna would last, especially if it were dropped once or twice.

In order to continue my test, I used some spare copper wire, removed all the waste solder and soldered the board to the foil. I decided not to even take a picture of that because it looks even worse. It will probably work better though.

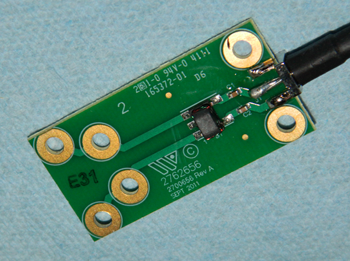

This is the circuit board inside the Winegard FlatWave. It’s not soldered at all. It seems to rely on pressure to keep the contacts together. There’s a little bit of glue inside the screw threads to hold it all together, and I have a feeling the solderless installation will work better.

The overall construction of this little board is much more impressive than the Mohu Leaf. The board itself is thicker, and because it’s not hand soldered it can have components on both sides. The cable is more securely fastened than in the Leaf, too.

Going strictly on appearances, the Winegard FlatWave wins 3-0. In the next article in the series, we’ll put them through actual testing to see how they act in real-world situations.